Lab Tool-kit Data Gathering for Lakes Studies 2023 at UCF

After extensive effort and countless hours of dedication, we have successfully developed a fully functional system that meets all of our expectations. This accomplishment was particularly challenging due to the significantly shorter duration of the summer semester compared to the Fall or Spring semesters.

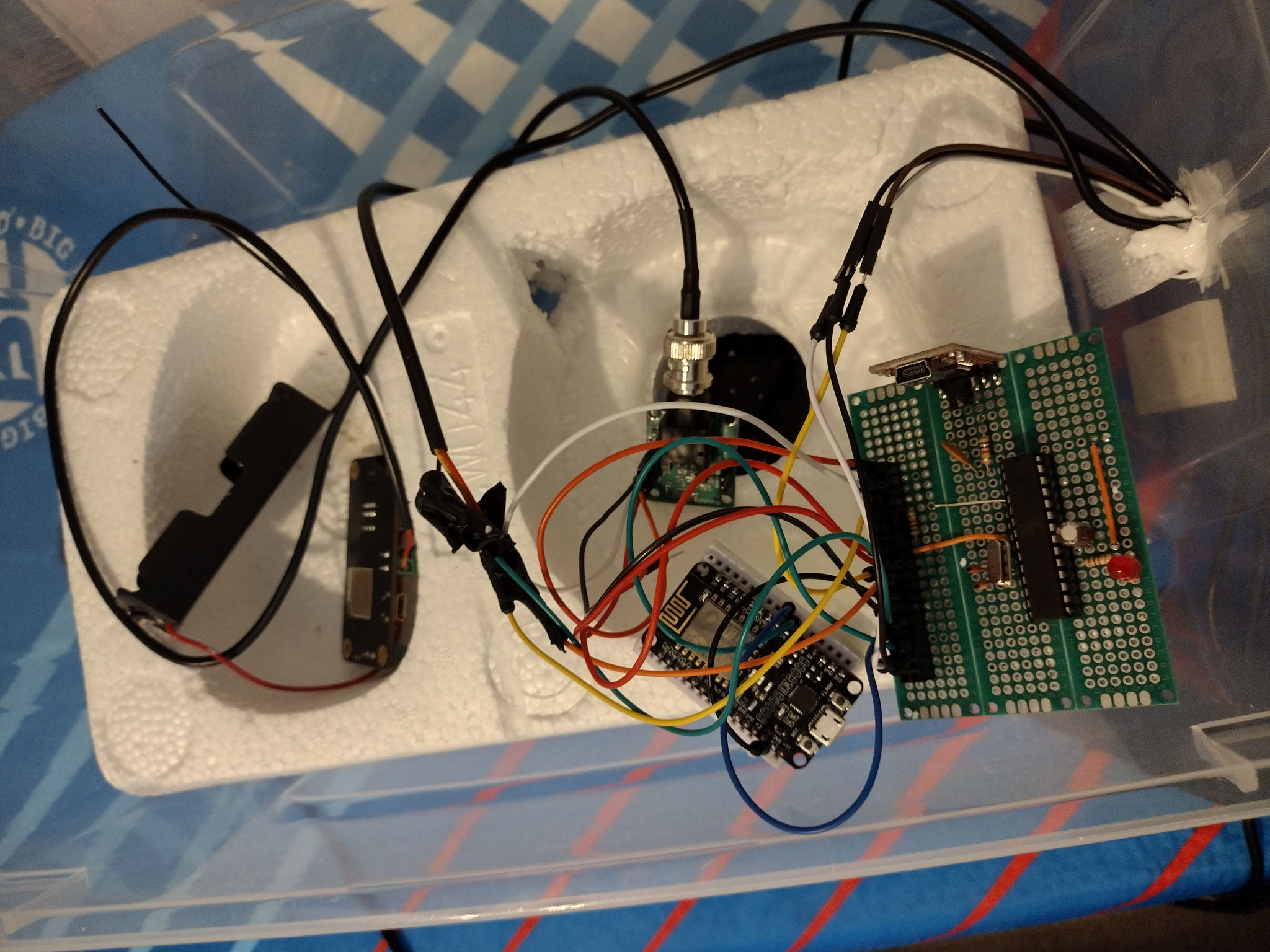

As a unified team, we have overcome the obstacles and managed to deliver a prototype that successfully incorporates software, water locomotion mechanics, and electronic design in a cohesive manner.

We proudly present the completed project by Engineering Group 07 at University of Central Florida UCF. Our First 100% Functional Prototype is able to:

1) It reads Water Temperature sensor

2) It reads Water pH sensor

3) It reads Air Temp sensor

4) It reads Air humidity sensor

4) All Sensors are sent in real time to the Cloud

5) Sensor data is stored in Database

6) Data Base is linked to a website that is protected with users' credentials.

7) Users can access Real Time data from the sensors in the form of tables or graphs.

8) The system can be remote controlled to any point in the lake

9) The system is able to collect organic material from the lake plus vegetal and insect species.

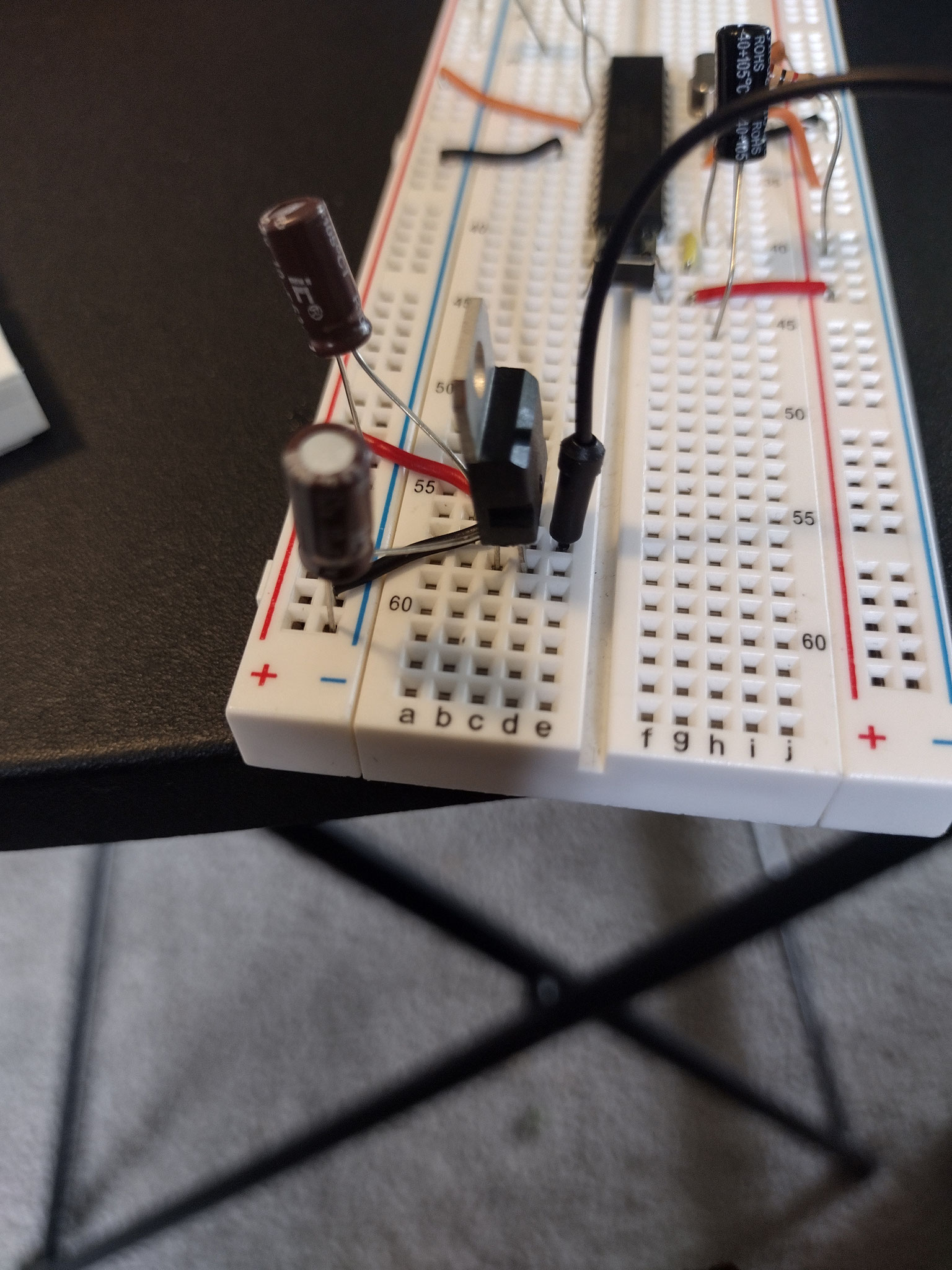

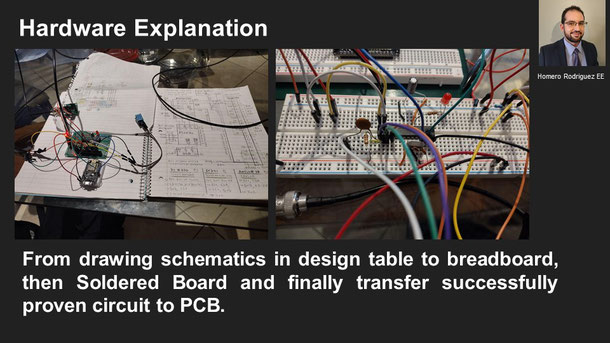

Since Summer term is significantly shorter than spring or fall and hardware development cycles take at least one week and a half from corrections and fabrication, the PCB fast development method shown above was implemented to maximize hardware success rate by providing 2 PCB prototypes per cycle instead of 1 prototype per cycle. At the end the team achieved 2 fully functional PCBs that were able to run the software and to manage all sensors and requirements as expected.

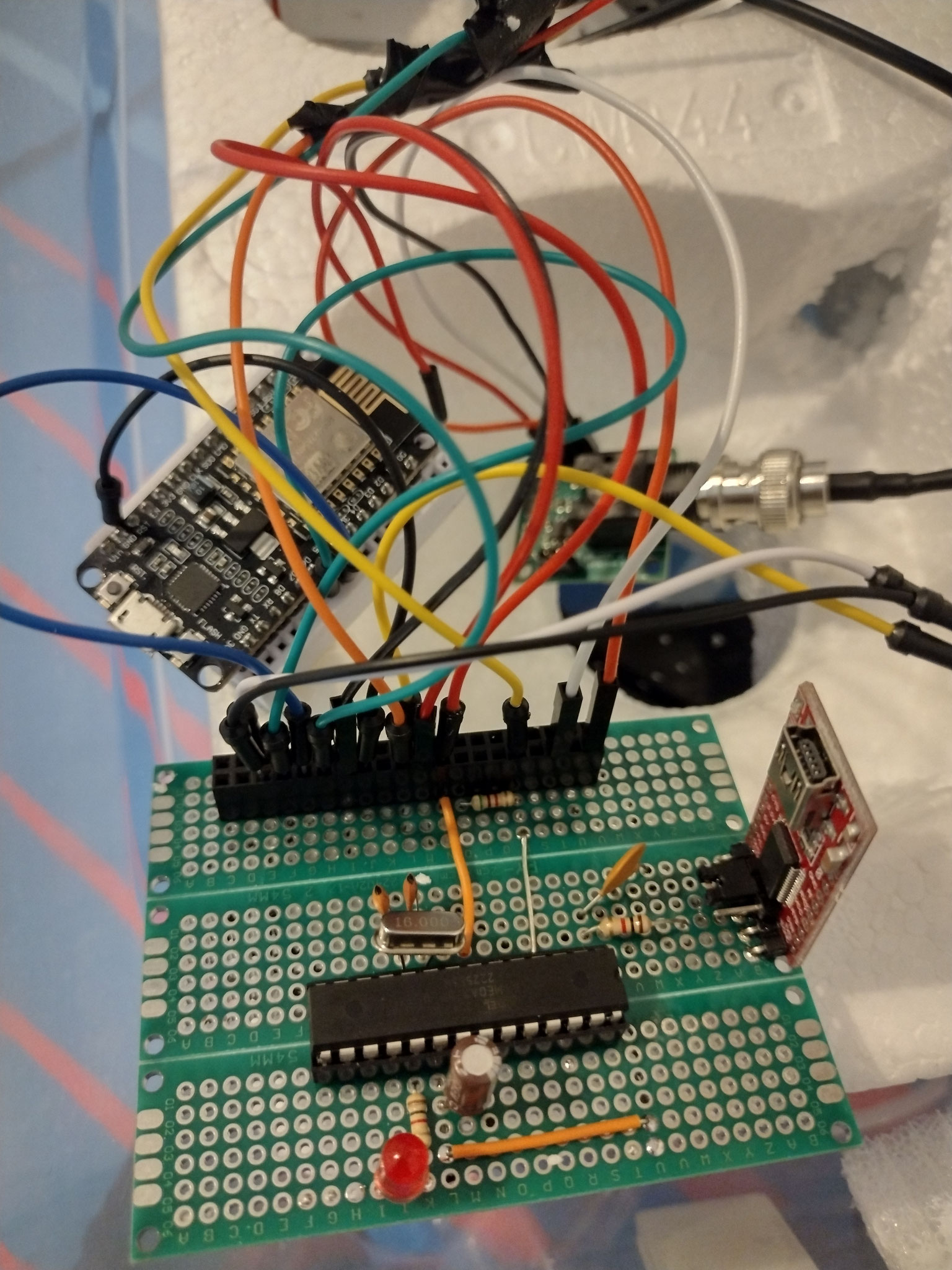

As it was explained, the soldered board was done from handmade schematics and prototyping. The soldered board was functional and able to manage the project as it was required. Then, the PCB board was fabricated according to previous specifications. The PCB has an additional power Jack and six ICSP programing pins just in case it has to be used to program bootloader in ATmega directly. It is important to note that ATmega is inserted into a 28 pins socket and it is not soldered to the board .

Lab Tool-kit working in the lakes

Hardware Electronics & Sensors

The PCB was designed with a customized topology that serves the project's purpose specifically and it also provided additional resources that could be needed if other sensors or electronics are needed to be connected in the future. The specialized Socket can be observed above with space for two IC2 sensors and a one 1 Wire Communications sensor with their respective Clock, Data, Ground and Power pins. There is also space for Clock and Data oscilloscope probes just in case some debugging is needed or if an analysis of those signals need to be performed.

Proto-typing and Soldered Board

Team 07 Members:

Ross Springstead

Homero Daniel Rodriguez

Ali Ahmed Al Khusaibi

Mina Younes

Zeid Haddadin

Work Distribution

The distribution of the work and responsibilities was assigned as shown above. More information about the project from components to system perspective can be found in the Slide Show below: